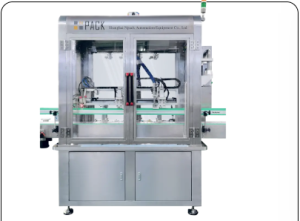

The ROPP capping machine is known for being fast, reliable and efficient in providing sealing services to bottles within the beverage, pharmaceutical as well as food industries. These ROPP highlighted impressions are developed from material sensations that affect the principle of product integrity and protection. Keep reading to find out just why an investment in a ROPP capping machine could be exactly what your production line is missing.

Enhanced Seal Integrity

Consumer Product SafetyTamper Evident Seals

The tamper-evident seals are the major benefit of ROPP capping. Impulse seals are essential for products that need to be safely enclosed such as food which could become contaminated or precious items where there is the risk of tampering. ROPP caps cannot be removed without showing visible evidence of interference, making the perfect soliton to give assurance to consumers and are a legal requirement for many pharmaceutical products along with food items.

Capping and Sealing at High Speed

Efficient Production Rates

These capping machines typically run a high number of bottles per hour, from hundreds to several thousand depending on the model chosen. This feature enables companies to greatly increase their productivity. As an example, there are some advanced machines that could process 1,200 bottles per hour per head-quite a throughput as your production rates cycle high-demand.

Cost-Effective Operation

Less Material and Operational Costs

An ROPP capping machine helps to save material as well as operation cost. Compared to other caps, ROPP feel more affordable because they are designed very simply and use less material. ROPP capping machines also offer automation that does not do nothing but ensure a significantly less expenditure and decreased error chances in human intervention.

Durability and Longevity

Built to Last

ROPP cappers are madeto last over long periods of industrial utilization. Built using top-grade raw materials like stainless steel, these equipments are resistant to any kind of wear and corrosion which makes them work for a longer lifespan without breaking down frequently. The durability of these machines results in reduced total cost of ownership and less frequent repairs or up dates.

Versatility Across Industries

Functional range: suitable for different types and sizes of bottles

These machines have a wide reach such that they can be used for capping of various kinds and sizes. This flexibility is especially useful for businesses that bundle many products or switch product lines on a seasonal basis. Its unique and robust mechanical design permits a fast setup of the machine corresponding to changing product dimensions for an uninterrupted production from one run to another within no time.

It is a sustainable packaging solution.

Aids in Environmental Objectives

ROP caps are seen as a move towards greener packaging The caps, which are fully recyclable through a closed-loop system that reduces environmental waste by boosting the pack's potential reusability, combine an easy-to-open snap feature with tamper evidence protection. ROPPl capping is a good strategy for companies attempting to improve their practices sustainably

Key Takeaway

When you are purchasing a ROPP capping machine, it adds lot of benefits in your production line. It serves not only the technical requirements for packaging today, but those supporting our larger business objectives of sustainability and cost management. This, in combination with the secure sealing they provide and a dedication to sustainability ensure that ROPP capping machine are an invaluable addition for any business taking their place within this competitive packaging industry seriously.